Are maize or corn knives worth the cost?

I was once given a set of finest Japanese’s chefs knives as present by someone who vastly overestimated my cooking skills. I didn’t complain at the time, and I’m not complaining now because although they haven’t improved my cooking, they have definitely improved my appreciation of well made stuff. There is something very satisfying about using tools that are a product of decades of honing the design and manufacture techniques. The Japanese are masters of this evolution and refinement, the term Shokunin means to become a master of your profession, but what the hell has this got to do with silage?

John Deere F9 chopping maize

What is the perfect way to chop silage?

So this is not in anyway an examination of the Japanese silage making expertises. No, this is all about the knives, and more importantly the knives inside the forage harvester. We spend an age considering the merits of different engine size and configurations, cab layouts and tyre combinations, but maybe we should be giving a bit more time to consider is the lumps of metal inside the chopper that actually do the chopping. So it is time to focus on the knife inside the forage harvester and to consider if it’s worth choosing different knives to chop different silage crops.

What is the best knife pattern for a forage harvester?

Now I’m not about to argue that a deep chevron pattern is better than a shallow one or that a multi knife drum is less efficient than a long knife set up. This is because anyone who tries to do that is probably just giving you their own opinion - the people who really know are the manufacturers R & D engineers. Anyone who has sat on a different coloured machine and declared that “this drum is the best thing since sliced bread” is missing all the other factors such and the engine torque characteristics, gearbox efficiency, feed roll compression rate etc etc.

Be in no doubt, each of the manufactures has sifted though hours of torque data, measured right at the drum input shaft, and they have chosen the optimum drum and knife layout design for their machine. So no I’m not looking at the drum design, right now I am really interested in the knife itself.

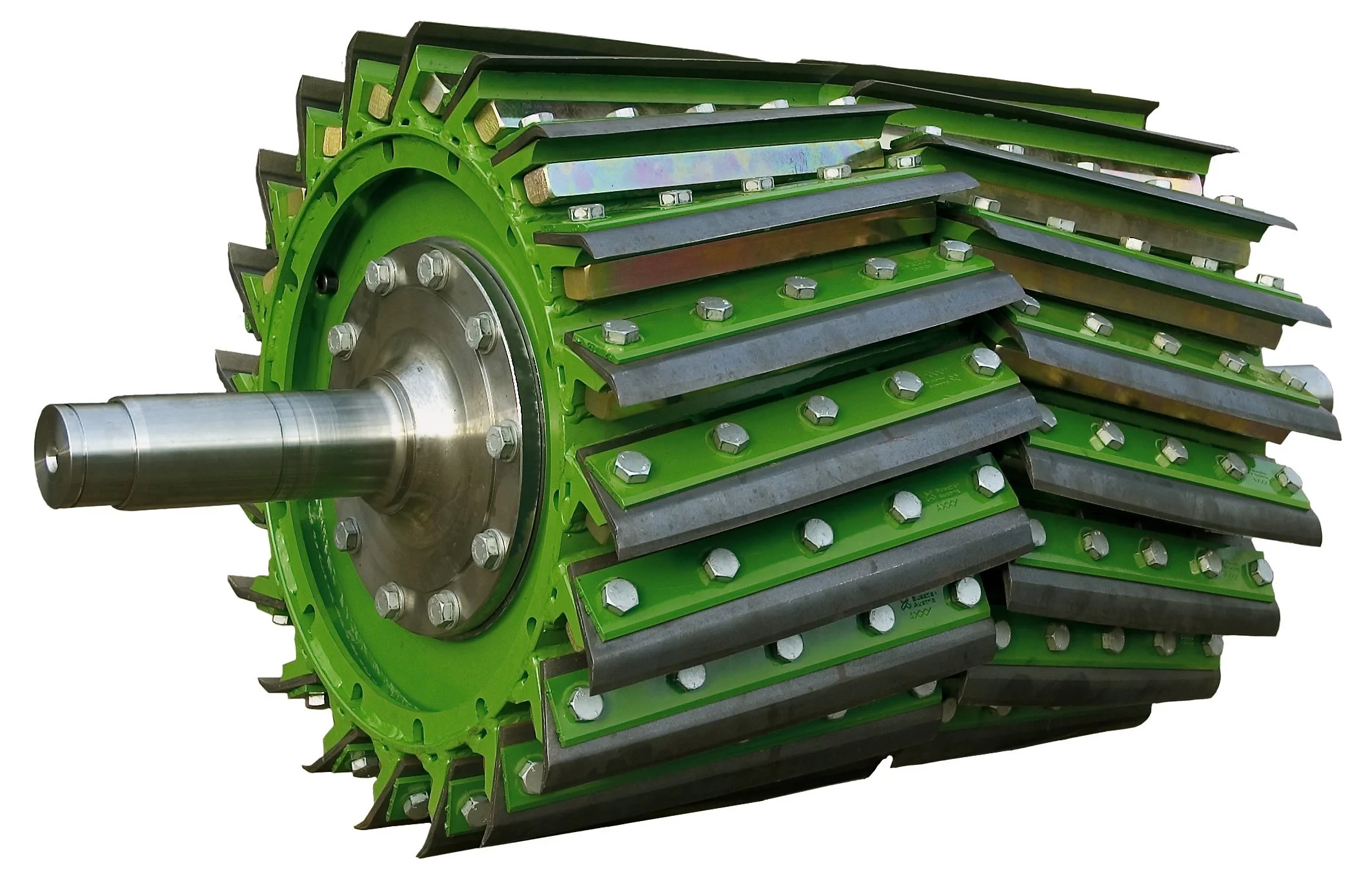

Krone Big X biogas drum and maize knives

The knife inside the forager is the real business end of the machine. It is the whole point of the operation, and it’s where the horsepower makes the difference. Maybe as much as 70% of the fuel you burn and the horsepower that it makes arrives right here at the cutting edge so it makes sense that you should focus on this bit to makes sure your getting the biggest chop for your buck.

Universal knives are good for all silage aren’t they?

The chances are your machine will come with some universal knives unless you particularly specify something else. And universal knives are great for just about every type of forage crop, but just about isn’t everything. A universal knife is really a grass knife to us in north west Europe. These knives have been optimised for chopping grass, particularly leafy tender grass and they are also capable of chopping maize and whole crop. What they are not really great at is high dry matter tough maize or maybe late whole crop.

Are maize knives worth the cost?

Maize knives are designed to make the most of all the horsepower in chopping these really tough silage crops like maize or corn - or so the manufactures would like you to believe - but are they really worth the extra cost to buy and change? Is this just marketing hot air or is a set of maize knives a good investment?

Well I think it probably is a good investment if you are chopping a decent amount of maize. That is because maize knives are made from a harder steel with higher carbon content. They are also slimmer than a grass knife and they stay sharper for longer in tough crops. Being slimmer means there is more space in the drum for a bulky crop. This all means maize or corn knives take less horsepower to drive than a grass or universal knife in maize silage.

New Holland FR920 harvesting corn silage

The saving in power results in a reduction of fuel cost per tonne harvested and an increase in tonnes per hour. So the numbers start to look more favourable. You then also need to remember that you’re not really paying twice for your knives if you choose two sets, because each set is doing only half the work. Tough maize eats universal knives but it can’t if they are sat on the shelf in the workshop. Obviously this wear rate depends on the split between grass and maize that you harvest, but in essence, two sets of knives need replacing half as often. The real cost is the time it takes to swap the knives over between crops.

So why not use maize knives for grass silage?

You’d think that would be a good idea, but it really isn’t. The high carbon hardened steel that maizes knives are made out of stays sharp for longer, but at a cost - and that cost is its brittleness and these knives are much more brittle than universals. The chances of picking up foreign material in a grass swath is much much higher than in a maize crop. The metal detector might save you from a stray rake tine, but it won’t help you if you pick up a stone or rock. That is why maize knives really need to be swapped out for universals if you're going back into grass.

Should you always buy genuine knives?

Eeeerrr this one is up to you, I’m not going to give you a strong view on genuine vs non-genuine. For me, honestly - I’m not brave enough to put an “aftermarket” or “pattern part” into the heart of such an expensive and critical piece of kit as a forage harvester. On the other hand, if everyone thought like me, then the manufactures and dealers could charge a fortune for key parts (some say they already do!). So I guess everyone has their own compass on genuine parts and you need to stick with that.

And don’t forget the shear bar.

It is obvious but it needs stating that the knife is only half of the story. The cutting is actually a scissor action between the moving knife on the drum and the stationary face that is the shear bar. Most machines have some form of automated shear bar adjustment, but you also need to check the face of the bar regularly and replace or rotate as per the manufacturers instructions.

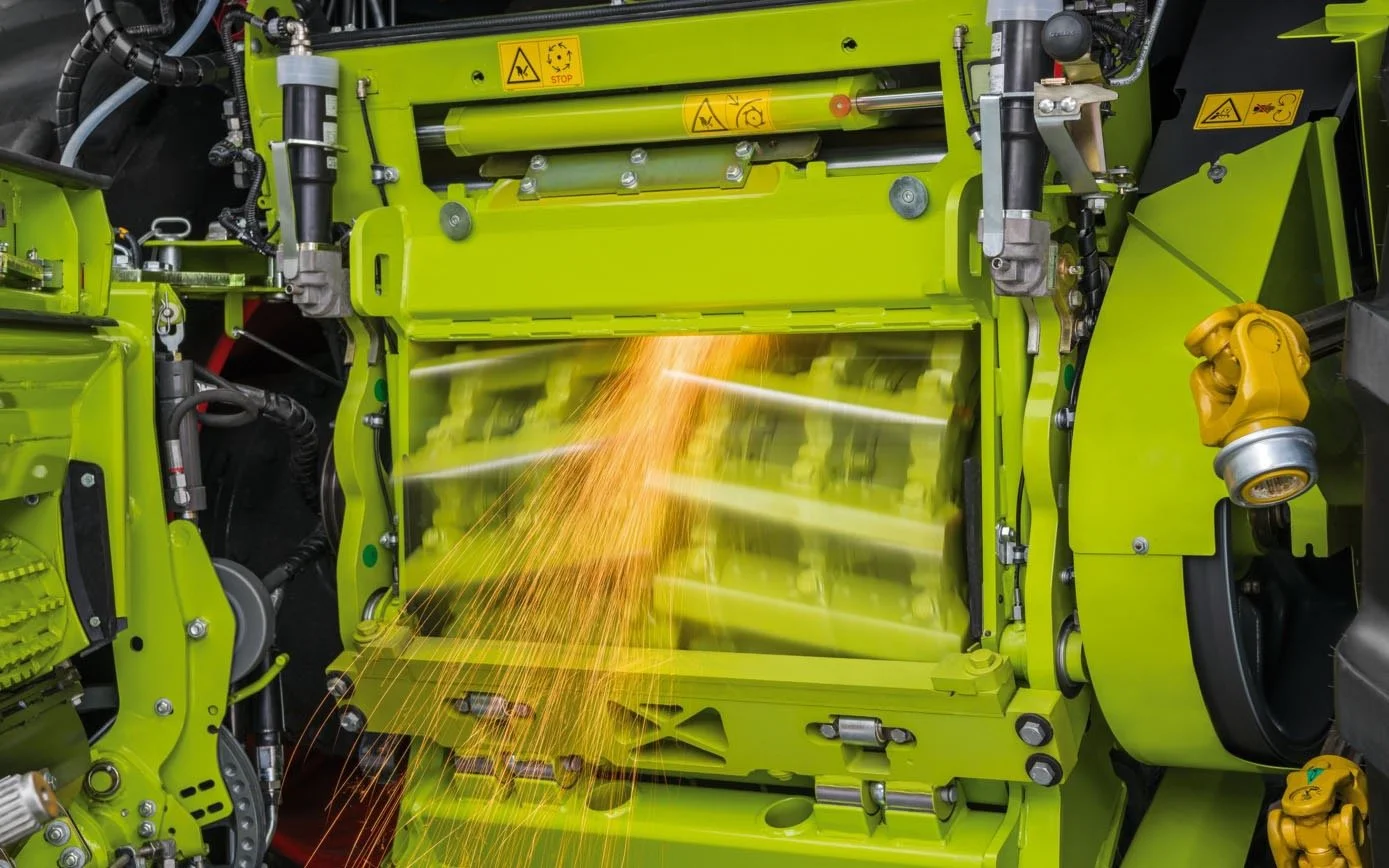

Sharpening Claas Jaguar chopper blades

Stay sharp

Ultimately It doesn’t matter what knives you have in there if you’re not keeping them sharp. Technology in the cab can give you an indication of the state of the knives as can a “seat of the pants” driver. Fuel use rises and forward speed drops as the edge goes off the performance, but the best way to keep on top of the knife is to inspect it, and yes that means getting out of the seat.

Unlike my kitchen knives, choosing the right knives for you harvester will make sure you do a better job. More importantly it will also make you a more efficient operator and should reduce your costs too.

If you want to discuss knives and shear bars or would like to discuss any other aspects covered in this series, contact me at jeremy@silageconsultant.co.uk